Marine

Marine construction presents many unique and challenging obstacles. Whether your need is inspection and repair of existing structures or design and construction of new structures, Bo-Mac has the experience and expertise necessary to develop a cost-effective, engineered solution for any marine problem. We stand behind our work and we do what is right.

Known for innovative thinking and employing cutting-edge technologies, Bo-Mac specializes in providing turnkey marine construction solutions designed to minimize facility disruption and downtime. We have extensive experience coordinating construction activities in proximity to in-service facilities, and our in-house fabrication capability allows us to minimize time on-site by employing modular project components where possible.

Equipment packages for any size project

We offer marine equipment packages suitable for all projects regardless of size, including:

- Small 50- to 100-ton barge cranes

- 225- to -250-ton barge cranes

- 300-ton capacity barge mounted ringer cranes

- 600-ton class ringer heavy lift barge

All marine barges are equipped with:

- Self-contained crew facilities

- Independent controlled spuds and winches

- Full complement of support equipment onboard

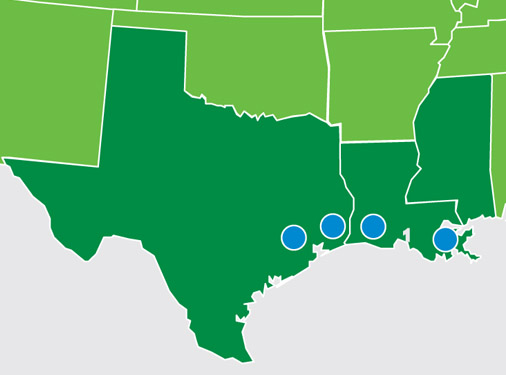

Fabrication near you

Our marine construction and fabrication facility is ideally located to meet the needs of the Texas and Louisiana Gulf Coast region. Situated on 30 acres of waterfront land along the Neches River and I-10 in Beaumont, Texas, it includes:

- Heavy modular and complete dock construction

- Large diameter over-length MonoPile construction

- Roll-on/roll-off bulkhead access

- Pre-cast concrete dock components

- Dry bulk conveyors and liquid handling loading arms

- LNG dock facilities and appurtenances

- Saving you time and money

Through our Early Contractor Involvement (ECI) process, we partner with you and your engineers to develop efficient concepts and construction methods, with an overriding emphasis on safety. Pre-fabricating components at our waterfront fabrication facility enhances safety, quality control and efficiency. Oversize components are easily transported to your facility and set in place with minimal facility disruption.

Our approach also includes:

- Dedicated project management

- On-site operations management

- In-house and third party quality assurance, quality control, and testing

- Professional engineered solutions

- Concept sketches and engineered drawings

Responsible, sustainable performance

Bo-Mac is committed to being good stewards of everything entrusted to us and that includes our environment:

- We use only environmental bio-degradable vegetable hydraulic oils

- Double containment for all fuel tanks

- Containment systems on all barge storage areas

- Noise dampening and vibration monitoring can be incorporated upon request